In most people’s minds, welding is a rough, gritty trade — molten metal, flying sparks, and thick gloves. But for those within the craft, welding can be something else entirely: an art form.

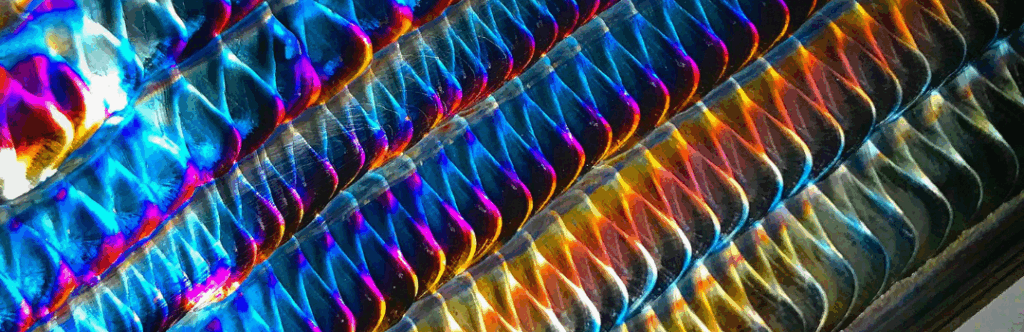

A well-executed weld is more than a structural necessity. It’s a thing of beauty — a shimmering stack of dimes that speaks volumes about the skill and control of the welder behind the hood. And today, thanks to platforms like Instagram and YouTube, welding as art has gained a global audience.

Let’s explore the most beautiful types of welds, what makes them so visually striking, and how this blend of precision and creativity is shaping the future of the craft.

What Makes a Weld Beautiful?

Beauty in welding is a mixture of symmetry, consistency, cleanliness, and precision. Whether you’re running TIG beads on stainless steel or creating flowing MIG welds on aluminum, a beautiful weld will have:

- Even spacing and uniform ripples (often called “stack of dimes”)

- Consistent penetration without spatter

- No undercut, porosity, or burn-through

- Clean surface with no slag residue or oxidation

- Intentional bead placement and edge blending

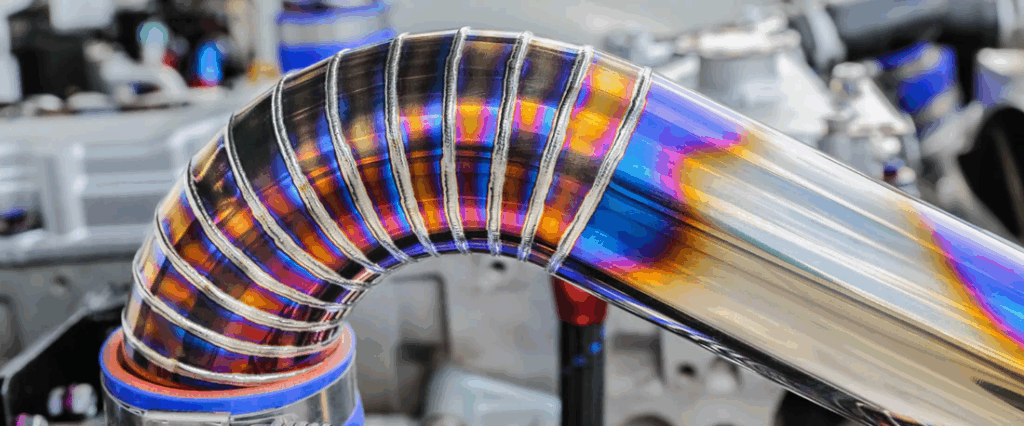

One of the most prized looks in welding is the TIG weld on stainless steel, which often produces a rainbow-like effect due to the heat and oxidation process. When done correctly, the result is a spectrum of purples, blues, golds, and silvers that shimmer across the metal — a true showpiece of technical mastery.

The “Stack of Dimes”: TIG Welding at its Finest

TIG (Tungsten Inert Gas) welding, especially on stainless steel and aluminum, is the king of beautiful welds. The process allows for extreme control, minimal spatter, and finely tuned heat input.

A perfect TIG weld will appear as a row of evenly spaced ripples, like coins stacked on their edge. It’s an effect that only comes from muscle memory, tight rhythm, and control of torch angle, travel speed, and filler rod feeding.

This style of weld has become so iconic that entire social media pages — like @weldporn, @welders_do_it_better, and @tiglife — exist just to celebrate this visual perfection.

Aluminum Weaves: MIG’s Shiny Counterpart

While TIG gets the glamour, MIG welding can also produce mesmerizing results, especially when using pulse settings on aluminum. The trick here is in the “weave” pattern, often done by hand or robotically in industries like automotive and aerospace.

Done well, a MIG weave on aluminum looks smooth and metallic, almost like brushed silver. Some welders have refined their weave patterns to a level of artistry that rivals decorative metalwork.

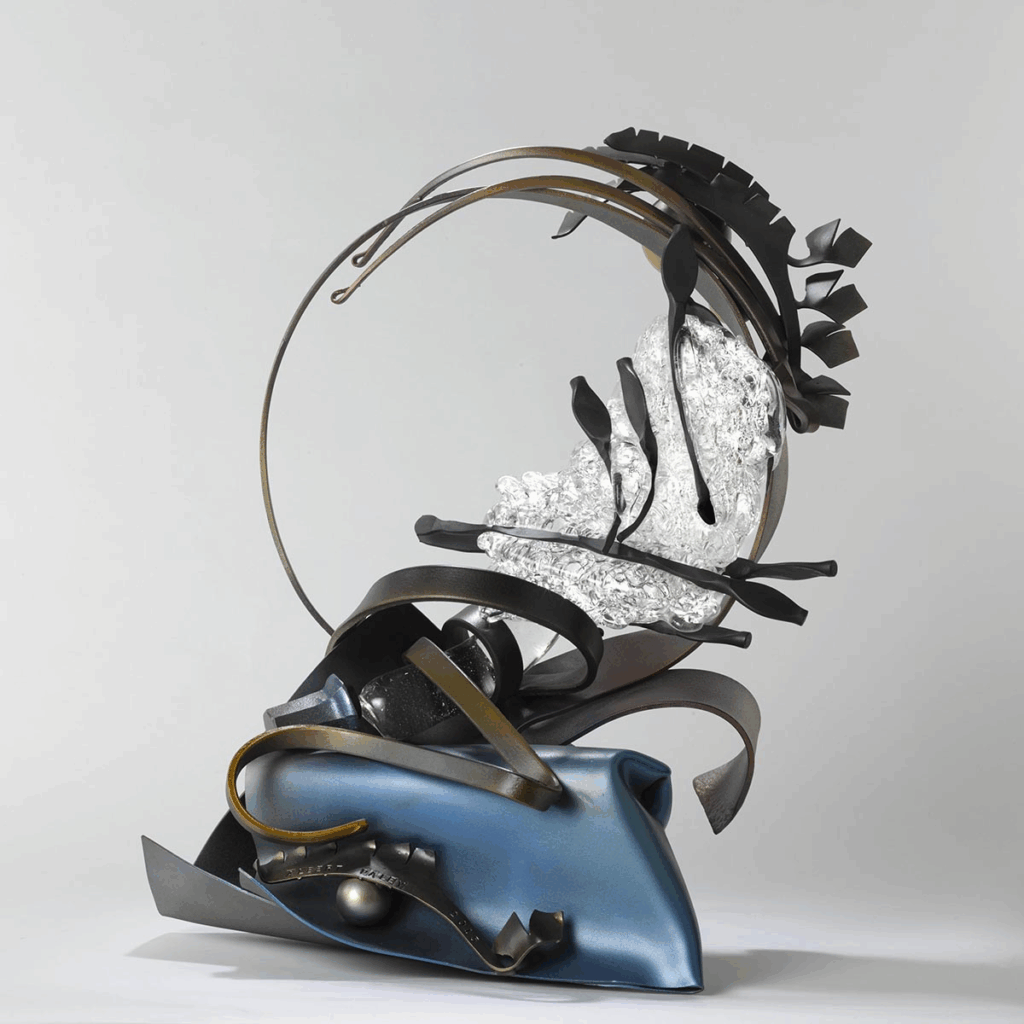

Welding as Sculpture: Functional Meets Creative

In recent years, welding has crossed over into the art world in a more literal sense. Welders are crafting sculptures, furniture, and even jewelry using nothing but raw metal and torch skill.

One of the most famous names in this field is Kevin Caron, a metal artist whose YouTube channel shows how traditional welding techniques can create stunning curves, twists, and abstract forms. His work proves that welding isn’t just about joining two pieces — it’s about transforming them into something new.

Another standout is Albert Paley, a renowned metal sculptor whose architectural installations feature sweeping, organic steel forms — many created with advanced welding and forging methods.

Common Materials That Make Beautiful Welds

Not all metals respond the same way under the torch. These are the most popular materials for eye-catching welds:

🔹 Stainless Steel

Produces colorful heat tints and takes a TIG weld bead beautifully. Common in food-grade, art, and performance automotive applications.

🔹 Aluminum

Highly reflective, difficult to master, but visually rewarding when done right. Excellent for both industrial and custom fabrication work.

🔹 Titanium

Gives off a vivid, rainbow-colored weld bead due to its reactivity. Used in aerospace, racing, and high-end exhaust systems.

Tools That Make Artistic Welding Possible

To achieve welds that are both strong and stunning, professionals use high-quality tools and settings. Here are a few standouts:

- Miller Dynasty 210 DX – Precision TIG with pulse control and AC/DC functionality.

- Lincoln Square Wave TIG 200 – Great for aluminum and beginner artists.

- Everlast PowerTIG 255EXT – Affordable yet powerful with waveform control for color-rich welds.

- Furick Cups – Pyrex TIG cups that offer better visibility for precision welds.

Using clear TIG cups and gas lenses allows better puddle control, more uniform gas flow, and tighter arc focus — key to creating consistent beads.

In summary…

A beautiful weld tells a story: of precision, focus, and hours of practice. It reflects both the strength of the material and the soul of the welder behind the mask.

As welding continues to blend utility with creativity, we can expect even more crossover between trade and art. For some, welding is about getting the job done. For others, it’s about leaving a signature — a bead so clean, so symmetrical, so vivid, that it becomes its own masterpiece.

In welding, beauty isn’t just in the eye of the beholder — it’s in the hand of the maker.

FAQ: The Art of the Weld

What makes a weld beautiful?

Beauty in welding comes from symmetry, consistent ripple spacing, proper penetration without spatter, clean surfaces with no porosity or undercut, and intentional bead placement and blending.

What is a “stack of dimes” weld and why is it admired?

It’s a TIG weld with evenly spaced ripples resembling stacked coins. Achieving it requires precise torch angle, travel speed, heat control, and filler timing—showcasing high-level control and rhythm.

Can MIG welding produce artistic-looking beads too?

Yes. With proper settings—often pulse on aluminum—a MIG weave can look smooth and metallic, producing clean, visually striking beads suitable for custom and aerospace-style work.

Which metals tend to create the most eye-catching welds?

Stainless steel, aluminum, and titanium are favorites. Stainless and titanium can show vivid heat tints; aluminum can appear like brushed silver when the weave and heat input are dialed in.

What tools or accessories help create consistent, color-rich welds?

High-quality TIG machines with pulse and AC/DC control, clear TIG cups and gas lenses for stable shielding, and proper setup all improve puddle control, gas coverage, and bead consistency.