When most people think of welding, they picture sparks flying in a garage or workshop. Maybe a welder bent over a frame, MIG torch in hand, radio humming in the background. But welding doesn’t always happen on solid ground.

Sometimes, it happens hundreds of feet above the earth, miles offshore, or even deep beneath the ocean’s surface. These are the environments where welders become more than tradespeople — they become adventurers, engineers, and survivalists.

Welcome to the world of extreme welding — a place where every spark carries risk, and every bead laid can mean the difference between disaster and success.

Beneath the Surface: Underwater Welding

You’re floating in a heavy, pressurized dive suit. The water is cold, even through the insulated layers. You can feel the ocean’s pressure bearing down on you, 100 feet below the surface. Visibility is low — just a few feet in front of your faceplate. You give a thumbs-up to your surface team, clamp the electrode to the steel pipe, and strike your arc. The water flashes as bubbles rise, hissing violently in your ears. You’re welding — at the bottom of the sea.

This is the life of an underwater welder, one of the most extreme and dangerous careers in the world. These welders combine the skills of a commercial diver and a structural welder, performing maintenance and repairs on submerged pipelines, oil rigs, bridges, dams, and naval equipment.

The Risks:

- Electric shock

- Explosive gas pockets

- Extreme water pressure

- Limited visibility

- Decompression sickness

Despite the dangers, underwater welders can make $100,000–$200,000 a year, depending on the depth, job location, and experience level.

One story comes from the Gulf of Mexico, where a team of saturation divers spent weeks in a pressurized chamber before diving 800 feet to repair a massive oil pipe leak. With every weld, they had to be precise — there was no going back. Any error could lead to a rupture. One diver later said, “It was like welding inside a giant pressure cooker — in slow motion, surrounded by blackness.”

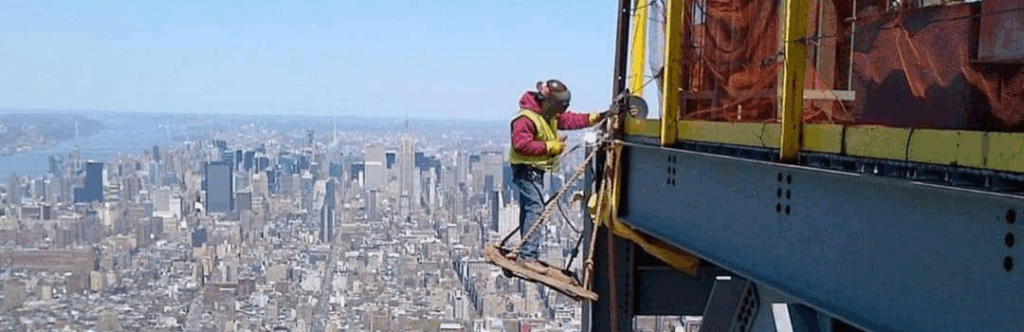

Above the World: High-Rise Iron Welding

You step onto a narrow steel beam, 60 stories up, wind whipping past your helmet. Below you, the city looks like a toy model. There’s no room for error. You hook into your harness, clip the leads to your belt, and crouch low. Your MIG torch roars to life as you fuse the skeletal frame of the future skyline together. This is your office — the sky.

High-rise structural welders are the backbone of modern urban development. They climb hundreds of feet into the air to assemble and secure the steel frames of skyscrapers, bridges, towers, and stadiums.

The Risks:

- Falls from extreme heights

- Shifting steel during crane lifts

- Exposure to wind, rain, and cold

- Fatigue and vertigo

While safety harnesses and nets have dramatically improved safety, the work is still dangerous. Welders must be comfortable balancing on beams just inches wide, sometimes in harsh weather, while focusing on precise welds.

In New York City, ironworkers and welders helped raise One World Trade Center to its towering 1,776 feet. Welders spent months working at over 1,000 feet, often in icy winds and blinding fog. One welder recalled, “You couldn’t see more than 10 feet ahead. But the steel still needed to be joined. When you’re up there, fear doesn’t help. Muscle memory and calm do.”

Working in the Wind: Tower and Wind Turbine Welders

You’re inside a narrow, echoing cylinder 300 feet above the ground. The metal shell creaks with every gust of wind. You’ve rappelled into the nacelle of a wind turbine. The sun’s setting, and you can see mountains in the distance. But right now, you’re locked in — grinding, welding, reinforcing the future of energy.

Wind turbine welders and tower welders take the skills of high-rise workers and apply them in remote, weather-exposed locations. These welders repair and maintain massive turbine blades and support columns — often accessed by climbing ladders inside the tower or rappelling with rope access gear.

The Risks:

- Climbing fatigue and confined spaces

- Mechanical hazards from moving parts

- Lightning risk on stormy days

- Remote emergency response times

Jobs can be found across the Midwest, Europe, and parts of Asia, where wind farms are rapidly growing. The job offers unmatched views — but you earn them with every foot you climb.

In Wyoming, a welder named Steve was tasked with repairing a cracked turbine housing at 280 feet. The wind gusts were hitting 35 mph. “We had to shut the whole field down,” he said. “You’re in a harness, hanging inside the nose of a machine the size of a bus. Every weld counts, because that turbine’s going to spin at 200 mph.”

Welding in the Wild: Remote Site Welding

You’re deep in the Alaskan wilderness, accessible only by helicopter. The temperature is 10°F. Your gear is on your back, and the pipe you’re repairing carries oil across the tundra. The generator hums, the steel is cold to the touch, and there are wolves not too far off. But you’ve got work to do — and only a few daylight hours left.

Remote welders travel to job sites in forests, deserts, mountains, and offshore platforms to perform emergency repairs or long-term builds. Often working in isolation, these welders rely on portable welding units, off-grid power, and self-reliance.

The Challenges:

- Isolation and logistical delays

- Unpredictable weather

- Wildlife hazards

- Mental and physical exhaustion

These welders are problem-solvers. They don’t just weld — they improvise, repair, and sometimes invent solutions with limited resources.

In British Columbia, pipeline welders often travel in by snowmobile, welding along icy ridgelines while avoiding avalanches. One welder noted, “You need to know more than just welding. You need to know how to stay alive.”

The Mental Game of Extreme Welding

Extreme welding isn’t just a physical challenge — it’s a psychological one. You need:

- Steady nerves

- Unwavering focus

- Precision under pressure

- Mental toughness in isolation or danger

Welders working underwater, at altitude, or in remote regions must train to control their fear, manage exhaustion, and make split-second decisions that could impact lives.

Many compare it to being in the military or elite sports: “There’s no room for panic. You breathe, you trust your training, and you weld like you’re on flat ground — even when you’re 700 feet in the air.”

The Future of Extreme Welding

As global infrastructure expands, extreme welding will only grow more important. Offshore wind farms, underwater data cables, mega bridges, and vertical cities all need welders who can go where others won’t.

And with the rise of automation, extreme welders may become more elite — focused on precision tasks that only humans can handle in unpredictable environments.

Training programs, like those offered at the Divers Institute of Technology or Lincoln Electric’s Advanced Welding School, are helping prepare the next generation of welders for a future that’s bold, high-tech, and high-risk.

In summary…

Welding is one of the few trades that can take you underwater, into the sky, and to the edge of the world. It’s hard, dangerous work — but for those who do it, it’s also deeply rewarding.

In the words of one tower welder: “Every time I strike an arc up there, it’s not just about steel. It’s about knowing I’m doing something that most people never will. I’m welding the bones of the world.”

FAQ: Extreme Welding

What counts as “extreme welding”?

Extreme welding happens in nontraditional, high-risk environments such as deep underwater, hundreds of feet in the air on high-rises or wind turbines, and in remote or harsh locations like tundra or offshore platforms. These roles demand advanced skill, physical conditioning, and strong mental focus.

What does an underwater welder do and what are the risks and pay like?

Underwater welders (often commercial divers) repair and build submerged structures—pipelines, bridges, dams, rigs, and naval equipment. Major risks include electric shock, gas pockets, high pressure, low visibility, and decompression sickness. Experienced professionals may earn roughly $100,000–$200,000 depending on depth, location, and experience.

Why is high-rise structural welding considered dangerous?

Working 60+ stories up exposes welders to falls, shifting steel during crane lifts, severe weather, and fatigue or vertigo. Even with harnesses and nets, the job requires precise welding while balancing on narrow beams in challenging conditions.

What do wind-turbine and tower welders handle day to day?

They climb inside tall towers or rappel to access nacelles and housings, performing grinding and weld repairs. Risks include confined spaces, moving parts, lightning exposure, and delayed emergency response in remote wind farms.

How can someone prepare for a career in extreme welding?

Build core welding skills and certifications first, then pursue specialty training: commercial diving for underwater work and rope-access/high-angle training for towers and high-rise jobs. Advanced programs (e.g., specialized commercial diving schools and advanced welding academies) help develop the precision and safety mindset required.